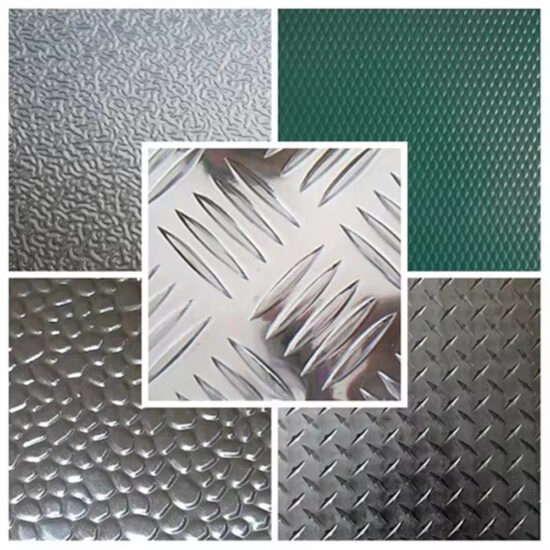

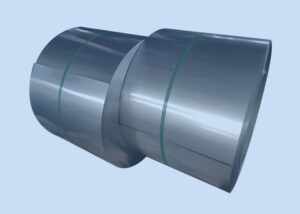

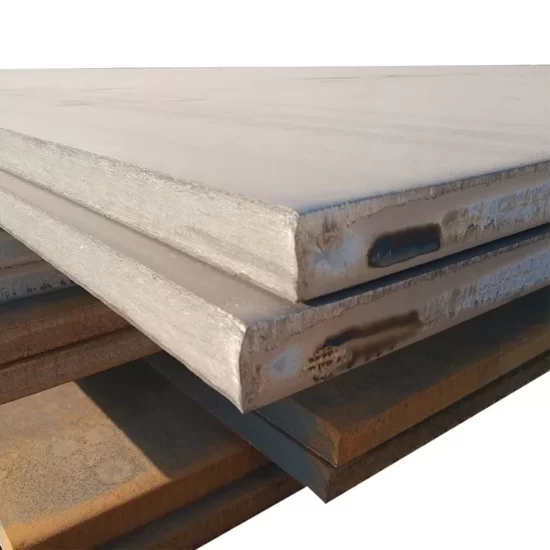

Thick aluminum plates are solid, flat sheets of aluminum that are characterized by their substantial thickness. Aluminum plates are manufactured through a process of casting or rolling, and their thickness can vary depending on the specific application requirements. Thick aluminum plates offer a range of features and applications:

- Strength and Structural Integrity: Thick aluminum plates provide high strength and structural integrity, making them suitable for applications that require load-bearing capacity and durability. They can withstand heavy loads and resist deformation under stress.

- Lightweight: Despite their thickness, aluminum plates are lightweight compared to other materials with similar strength properties, such as steel. This makes them advantageous in applications where weight reduction is critical, such as aerospace, transportation, and marine industries.

- Corrosion Resistance: Aluminum has natural corrosion resistance, forming a protective oxide layer on its surface that prevents further oxidation. Thick aluminum plates are widely used in corrosive environments, including marine, chemical processing, and offshore applications.

- Heat Dissipation: Aluminum has excellent thermal conductivity, making thick aluminum plates effective in heat dissipation and heat transfer applications. They are used in heat sinks, cooling systems, and other thermal management applications.

- Machinability: Thick aluminum plates are easily machinable, allowing for various fabrication processes such as cutting, drilling, milling, and shaping. This enables them to be customized and adapted to specific requirements.

- Versatility: Thick aluminum plates have a wide range of applications across industries, including aerospace, automotive, construction, marine, industrial equipment, and structural components.

Some common applications of thick aluminum plates include:

- Aerospace structural components, including aircraft wings, fuselage panels, and landing gear parts.

- Heavy-duty transportation equipment, such as truck beds, trailers, and railcar components.

- Industrial machinery, including base plates, frames, and support structures.

- Construction and architectural applications, such as bridges, building facades, and structural beams.

- Heat exchangers, boilers, and other thermal management systems.

- Marine vessels, including hulls, decks, and superstructures.

- Chemical processing equipment and storage tanks.

In summary, thick aluminum plates offer a combination of strength, lightweightness, corrosion resistance, heat dissipation, machinability, and versatility. These properties make them well-suited for a wide range of industrial, commercial, and structural applications where durability, performance, and design flexibility are essential.

QIDAMT

QIDAMT