Spacification

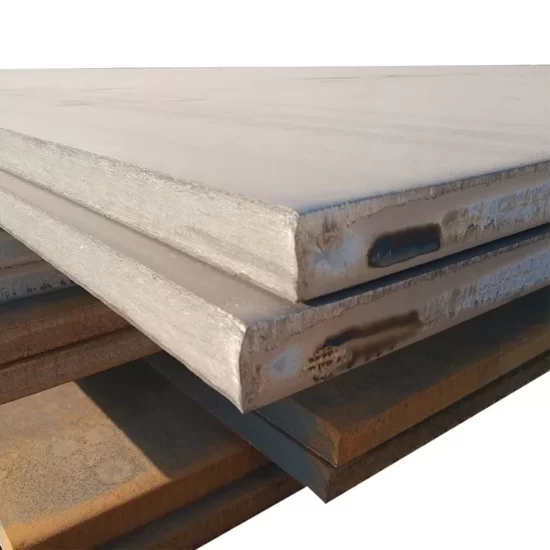

AISI 1045 steel is a medium tensile steel supplied in a black hot-rolled or normalized condition. It has a tensile strength of 570 – 700 MPa and Brinell hardness ranging between 170 and 210.

AISI 1045 steel is characterized by good weldability, good machinability, and high strength and impact properties in either the normalized or hot-rolled condition.

AISI 1045 steel has a low through-hardening capability with only sections of around 60 mm in size being recommended as suitable for tempering and through-hardening. However, it can be efficiently flame- or induction-hardened in the normalized or hot rolled condition to obtain surface hardnesses in the range of Rc 54 – Rc 60 based on factors such as section size, type of set up, quenching medium used etc.

AISI 1045 steel lacks suitable alloying elements and hence does not respond to the nitriding process.

Chemical Composition

| Element | Content |

|---|---|

| Carbon, C | 0.420 – 0.50 % |

| Iron, Fe | 98.51 – 98.98 % |

| Manganese, Mn | 0.60 – 0.90 % |

| Phosphorous, P | ≤ 0.040 % |

| Sulfur, S | ≤ 0.050 % |

Physical Properties

| Physical Properties | Metric | Imperial |

|---|---|---|

| Density | 7.87 g/cc | 0.284 lb/in3 |

Mechanical Properties

| Mechanical Properties | Metric | Imperial |

|---|---|---|

| Hardness, Brinell | 163 | 163 |

| Hardness, Knoop (Converted from Brinell hardness) | 184 | 184 |

| Hardness, Rockwell B (Converted from Brinell hardness) | 84 | 84 |

| Hardness, Vickers (Converted from Brinell hardness) | 170 | 170 |

| Tensile Strength, Ultimate | 565 MPa | 81900 psi |

| Tensile Strength, Yield | 310 MPa | 45000 psi |

| Elongation at Break (in 50 mm) | 16.0 % | 16.0 % |

| Reduction of Area | 40.0 % | 40.0 % |

| Modulus of Elasticity (Typical for steel) | 200 GPa | 29000 ksi |

| Bulk Modulus (Typical for steel) | 140 GPa | 20300 ksi |

| Poissons Ratio (Typical For Steel) | 0.290 | 0.290 |

| Shear Modulus (Typical for steel) | 80 GPa | 11600 ksi |

Applications

AISI 1045 is widely used for all industrial applications requiring more wear-resistance and strength. Typical applications of AISI 1045 are as follows:

| Gears | Pins | Rams |

| Shafts | Rolls | Sockets |

| Axles | Spindles | Worms |

| Bolts | Ratchets | Light gears |

| Studs | Crankshafts | Guide rods |

| Connecting rods | Torsion bars | Hydraulic clamps |

Heat Treatment

AISI 1045 is subjected to forging, annealing, normalizing, stress-relieving, hardening and tempering processes – each of which is explained in more detail below:

- Forging – Heat to 850°C – 1250°C (1562°F – 2282°F). Hold until the temperature is uniform. Cool in a furnace.

- Annealing – Heat to 800°C – 850°C (1472°F – 1562°F). Hold until the temperature is uniform. Cool in a furnace.

- Normalizing – Heat to 870°C – 920°C (1598°F-1688°F). Hold until the temperature is uniform. Soak for 10 – 15 minutes. Cool in still air.

- Stress-Relieving – Heat to 550°C – 660°C (1022°F – 1220°F). Hold until the temperature is uniform. Soak for 1 hour per 25mm of section. Cool in still air.

- Hardening – Heat to 820°C – 850°C (1508°F – 1562°F). Hold until the temperature is uniform. Soak for 10 – 15 minutes per 25mm of section. Quench in water or brine.

- Tempering – Re-heat to 400°C – 650°C (752°F – 1202°F) as required. Hold until the temperature is uniform. Soak for 1 hour per 25mm of section. Cool in still air.

Applications

AISI 1045 is widely used for all industrial applications requiring more wear-resistance and strength. Typical applications of AISI 1045 are as follows:

| Gears | Pins | Rams |

| Shafts | Rolls | Sockets |

| Axles | Spindles | Worms |

| Bolts | Ratchets | Light gears |

| Studs | Crankshafts | Guide rods |

| Connecting rods | Torsion bars | Hydraulic clamps |

QIDAMT

QIDAMT