7075 Produktdetails von Aluminiumlegierungblättern

Der 7075 Aluminium -Leichtmetallblech zeichnet sich in zahlreichen Bereichen mit seiner hervorragenden Leistung aus und ist zu einem unverzichtbaren und wichtigen Material in der modernen industriellen Herstellung geworden.

ICH. Produkteigenschaften

- Hohe Stärke: 7075 Aluminiumlegierung gehört zur Serie Al-Zn-Mg-Cu Super Duralumin und ist eine der mächtigsten kommerziellen Legierungen. Nach Wärmebehandlung, Es kann extrem hohe Stärke aufweisen. Seine Zugfestigkeit kann erreichen 524 Mpa, und die 0.2% Ertragsfestigkeit erreicht 455 Mpa, weit über den von Weichstahl hinaus, Bereitstellung einer soliden Garantie für Anwendungen mit verschiedenen hochfesten Anforderungen.

- Gute mechanische Eigenschaften: Es hat hervorragende umfassende mechanische Eigenschaften. Zum Beispiel, Es hat eine gute Duktilität, mit einer Verlängerungsrate von bis zu 11%, enabling it to adapt to complex processing techniques to a certain extent without easily breaking. Gleichzeitig, it has a relatively high elastic modulus of 71 Gpa, ensuring the stability and rigidity of the material under stress.

- Excellent Machinability: The material is easy to process. The fine grains make the deep drilling performance more outstanding. During the machining process, the wear resistance of tools is enhanced, and thread rolling is smoother and more efficient, greatly improving production efficiency and product quality.

- Corrosion and Oxidation Resistance: It has ordinary corrosion resistance and can effectively resist the erosion of corrosive media in general environments. Darüber hinaus, it has good oxidation resistance. A dense oxide film can form in the air to protect the internal metal from further oxidation, extending the service life of the product.

- Significant Heat Treatment Strengthening Effect: Through appropriate heat treatment processes, its strength, hardness, and other properties can be significantly improved to meet the diverse requirements of different engineering scenarios for material properties.

II. Chemische Zusammensetzung

|

Element

|

Inhalt

|

|

Silizium (Und)

|

0.40

|

|

Eisen (Fe)

|

0.50

|

|

Kupfer (Cu)

|

1.2 – 2.0

|

|

Mangan (Mn)

|

0.30

|

|

Magnesium (Mg)

|

2.1 – 2.9

|

|

Chromium (Cr)

|

0.18 – 0.28

|

|

Zinc (Zn)

|

5.1 – 6.1

|

|

Titanium (Von)

|

0.20

|

|

Aluminium (Al)

|

Balance

|

|

Others

|

Single: 0.05 Total: 0.15

|

Zinc, as the main alloying element in 7075, forms MgZn₂ with an appropriate amount of magnesium, which greatly enhances the strength of the alloy. Meanwhile, the addition of small amounts of alloying elements such as copper and chromium further optimizes the comprehensive properties of the alloy.

III. Mechanische Eigenschaften

|

Performance Index

|

Wert

|

|

Tensile Strength σb (MPa)

|

≥560

|

|

Yield Strength at 0.2% Offset σp0.2 (MPa)

|

≥495

|

|

Elongation at Break δ5 (%)

|

≥6

|

|

Härte

|

150HB

|

|

Dichte

|

2810 kg/m³

|

|

Elastic Modulus E/Gpa

|

71

|

IV. Application Fields

- Aerospace Industry: With its high strength and low density, it has become an ideal material for manufacturing aircraft structural components, such as aircraft beams, wings, landing gears, and other key parts. It effectively reduces the weight of the aircraft, improves flight performance and fuel efficiency, and ensures the safety and reliability of the structure.

- Mold Manufacturing: It is widely used in the manufacturing of various molds, such as blow (bottle) molds, ultrasonic plastic welding molds, golf club head molds, shoe molds, paper-plastic molds, foam molding molds, and dewaxing molds. Its good wear resistance and machinability ensure the high precision and long service life of the molds.

- Mechanical Equipment: It is used to manufacture various components of mechanical equipment, such as gears, shafts, high-strength bolts, usw., meeting the strict requirements of equipment for material strength and reliability and ensuring the stable operation of the equipment.

- Other Fields: It also performs outstandingly in construction and engineering fields that require high-strength materials, such as tower buildings, shipbuilding, pipelines, and some high-end sports equipment, such as bicycle frames.

V. Product Specifications

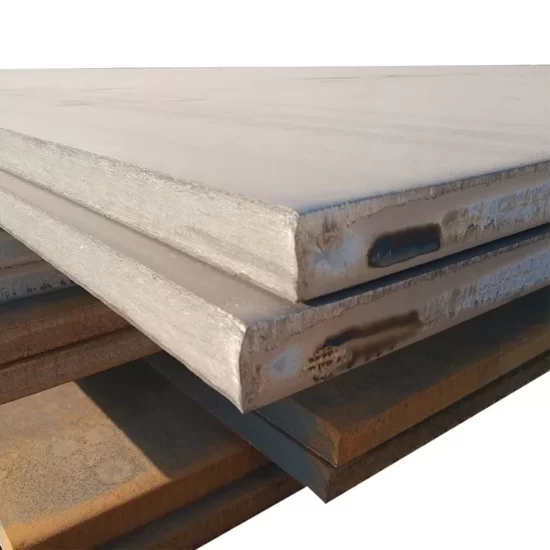

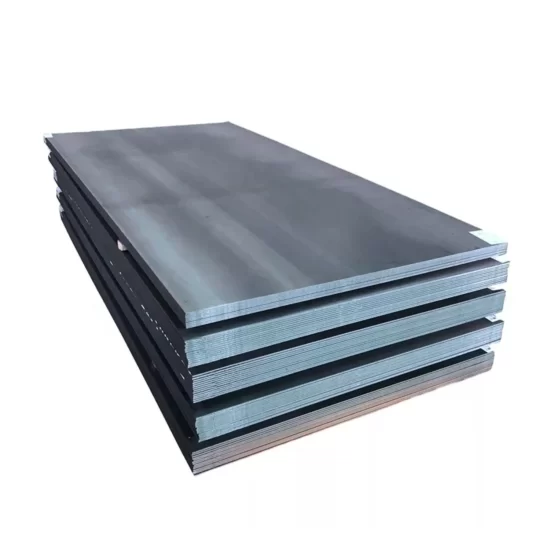

We offer a wide range of 7075 aluminum alloy sheet specifications. The thickness ranges from 4mm to 20mm, and common sizes include 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 20mm. The length and width of the sheets can be customized according to customer requirements, such as 100mm×100mm, 200mm×200mm, usw. Other special sizes can also be provided to meet the personalized needs of different projects.

VI. Product Advantages

- Reliable Quality: We strictly follow international standards and industry norms in production. From raw material procurement to product delivery, multiple quality inspection processes are carried out to ensure that each aluminum alloy sheet has stable and excellent performance.

- Customized Services: We can provide customized product sizes, processing techniques, and surface treatment solutions according to specific customer requirements to meet the special requirements of different application scenarios.

- Professional Team: We have an experienced technical team that can provide professional technical consultations and solutions to help customers make the best decisions in material selection and application.

- Perfect After-sales Service: We have established a complete after-sales service system, responding promptly to customer feedback and solving problems encountered by customers during use, so that customers have no worries.

Choosing our 7075 aluminum alloy sheet means choosing a high-quality and high-performance material solution to contribute to the success of your project. If you have any needs, please feel free to contact us.

FORTSCHRITT

FORTSCHRITT